How to Use Water Commander Effectively in 2026 for Optimal Performance?

In 2026, optimizing the use of the water commander is crucial. Expert hydrologist Dr. Emily Carter emphasizes, "Using water commanders efficiently can transform water management." This highlights the importance of effective application methods.

Understanding the water commander’s features can lead to better performance. However, many users face challenges. Common pitfalls include improper setup and maintenance neglect. These mistakes can hinder performance and waste resources.

Good practices involve regular checks and updates. Having a plan is essential. Yet, many still overlook these steps. Reflecting on usage methods is necessary. The water commander offers significant benefits, but only if used wisely. This balance of diligence and knowledge can lead to optimal performance.

Understanding the Water Commander System and Its Components

The Water Commander system plays a crucial role in ensuring optimal water management. Understanding its components is essential for effective use. At the heart of the system is the pump, which maintains water pressure. It’s vital to check its performance regularly. A faulty pump leads to inefficiency, wasting energy and resources.

Another key component is the control unit. This part manages the operation of the system. If it malfunctions, users might face irregular water supply. Users should familiarize themselves with its settings. Many struggle with adjustments, often neglecting these details.

Lastly, filters are essential for clean water delivery. Clogged filters can reduce water quality. Regular maintenance is often overlooked, yet it's crucial. Users tend to remember the pump but forget filters. Without routine checks, the system suffers. Understanding each component helps users optimize performance. It’s a continuous learning process. Balancing these aspects can lead to improved efficiency but requires diligence.

Water Commander Performance Metrics in 2026

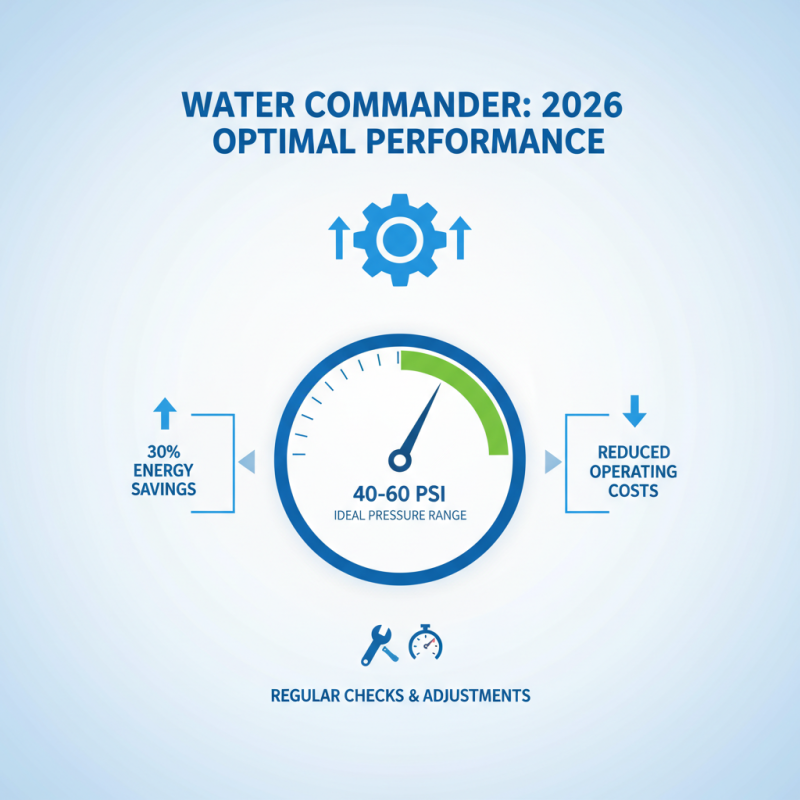

This chart illustrates the key performance metrics of the Water Commander system in 2026, focusing on efficiency, pressure, flow rate, and durability. These metrics are essential for users to understand how to utilize the Water Commander for optimal performance.

Setting Up Your Water Commander for Maximum Efficiency

Setting up your Water Commander efficiently can truly enhance your overall performance. Begin by choosing a suitable location. Ensure it has ample space, away from direct sunlight and moisture. Indoor settings are preferred. Consider accessibility for maintenance. It’s essential to have a clear area around the unit for future adjustments.

Tips: Regularly check connections for leaks. A small drip can waste resources and affect performance. Also, ensure the power source is reliable. Interruption can lead to malfunction or inefficiency. Use stabilizers if needed.

Calibration is another critical step. Adjust settings according to your specific needs. Monitor the output closely for the first few weeks. Look for any unexpected fluctuations. If something feels off, be ready to tweak your settings. It's a learning process; don’t hesitate to experiment.

Tips: Document changes you make for future reference. This will help in troubleshooting. Identify patterns that work best for your environment and use them. Analyzing your data can prevent frustration later on.

Best Practices for Operating Water Commander in Various Conditions

Using a Water Commander effectively in 2026 requires attention to operational best practices. Different conditions demand unique approaches to get optimal performance. According to recent industry data, systems operating with a pressure range of 40-60 PSI outperform others in efficiency, reducing energy costs by up to 30%. This emphasizes the need to regularly check pressure settings and adjust them as the environment changes.

Tip: Always calibrate your Water Commander after heavy rainfall or seasonal changes. Fluctuating water levels can affect performance significantly. In dry conditions, ensure that your equipment is well-maintained and free from debris, as this can hamper water flow.

Operating in varied terrains can also present challenges. Reports show that systems in hilly areas tend to lose pressure more rapidly. Adjusting the layout of supply lines can mitigate this issue, ensuring consistent flow. However, bear in mind that not all modifications yield expected results. Each installation might need its own evaluation.

Tip: Keep a log of adjustments and their outcomes. This can help identify patterns, leading to more informed decisions. Regular assessments are essential to maintaining performance and preventing unexpected failures. Understanding your specific environment is crucial for achieving the best results over time.

Troubleshooting Common Issues with Water Commander Systems

Water Commander systems provide essential service in managing water flow efficiently. However, users may encounter common issues over time. Addressing these problems can ensure optimal performance and longevity of the system.

One frequent issue is low water pressure. This often stems from clogged filters or malfunctioning pipes. Regularly checking these components can prevent this problem. A simple inspection can reveal debris buildup that hampers flow. Clear any blockages you find. Additionally, ensure that all connections are secure to avoid leaks.

Another common challenge is unexpected shutdowns. This could indicate electrical issues or software glitches. It's crucial to keep the software updated for improved stability. If irregular shutdowns persist, conduct a hardware check. Loose wires can cause interruptions, leading to bigger problems. Pay close attention to system alerts that might indicate these faults. Routine maintenance is the key to keeping the system running smoothly, but it requires diligence.

Maintaining Your Water Commander for Long-Term Performance Stability

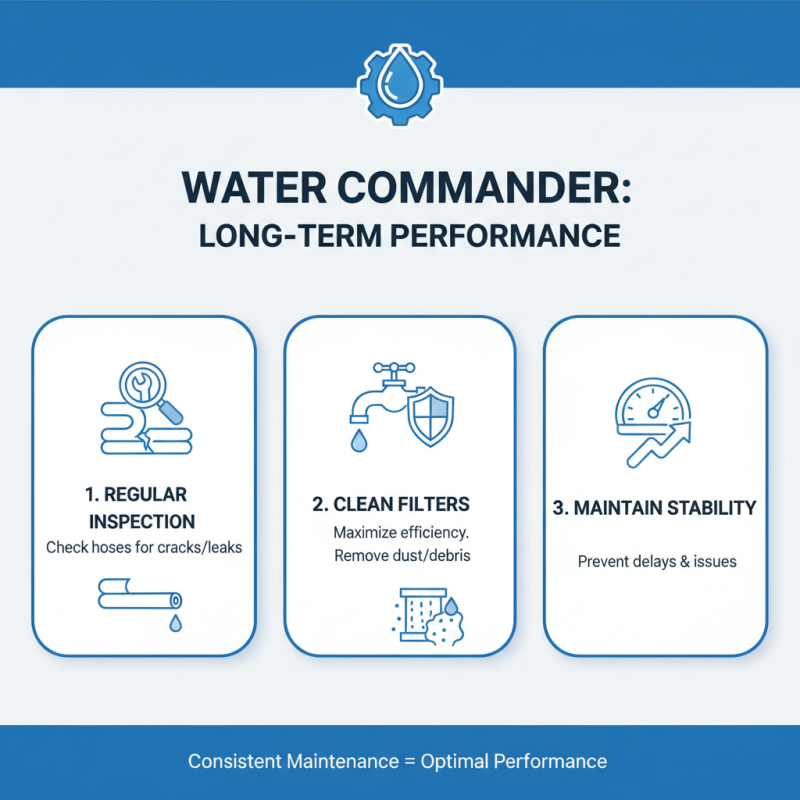

Maintaining your water commander is crucial for long-term performance stability. Regular inspection of key components is essential. Check hoses for cracks or leaks. This could lead to significant issues if ignored. Cleaning filters regularly will also help maximize efficiency. Dust and debris can accumulate, causing operation delays.

Flushing the system occasionally is another important step. It prevents sediment buildup that could affect water flow. Pay attention to the pressure settings as well. The right pressure ensures optimal performance, while incorrect settings may stress the system. Keep a maintenance log to track changes and repairs. This fosters a better understanding of its operational patterns.

Don’t overlook the importance of winterizing the system if required. Freezing temperatures can harm many components. Taking proactive measures can save time and costs later. Identifying potential problem areas before they escalate is key. Engage in routine checks to foster reliability. Your system needs consistent attention for a long-lasting, effective performance.

Related Posts

-

How to Choose a Home Sump Pump for Maximum Basement Protection in 2025

-

How to Choose the Best Backup Power for Your Sump Pump to Prevent Flooding

-

2026 Best Sump Pump Backup Battery Options for Homeowners

-

2025 Top 5 Suction Pumps You Need to Know for Effective Solutions

-

Top 2025 Battery Backup Sump Pumps: Ensure Your Home Stays Dry

-

2025 Top 5 Backup Sump Pump Batteries: Ultimate Guide for Homeowners